Broken charge port

Yesterday, the charge port of the e-Golf broke. Last Friday, I was unable to remove the plug from the car, but eventually I managed to get it out. Then on Saturday, I wanted to charge the car again, but this time the plug would not lock. Although charging would commence on the charge point, the car gave a red LED indication on the charge port. I tried to swap the cable with another one, and I finally managed to charge it again. Until yesterday, when I could not get it to work, no matter how often I tried.

With less than 50 kilometers of range, I was able to drive it to the local dealer. Although this was not the dealer where I bought the car, I did not have any choice. The car still has warranty, and I was allowed to get it repaired at any authorized Volkswagen dealer.

At the dealer, they confirmed that the charge port was broken, and the root cause is the locking motor. It is a common failure mode that also occurs on other Volkswagen models that have the same charge port design. The locking motor is directly connected to the wiring loom, so according to a repair instruction (TPI 2051071/6), a replacement part can be connected by cutting the wiring loom and splicing in a new connector.

I was lucky that this was covered by warranty. It blew my mind when I heard that the replacement part was over 300 euros (excluding labor costs). I know that repair parts can be expensive, but for something that is just an RC motor with a few plastic gears, it is quite a lot. For the newer models such as the ID.3 and ID.4, this motor can be replaced separately and only costs about 50 euros. And besides that, I was able to find the same motor for a fraction of the price for the e-Golf. OK, I do have to add a connector to it, but still. Nonetheless, I am happy that the car is fixed, and fast. The dealer did a great job in getting it quickly.

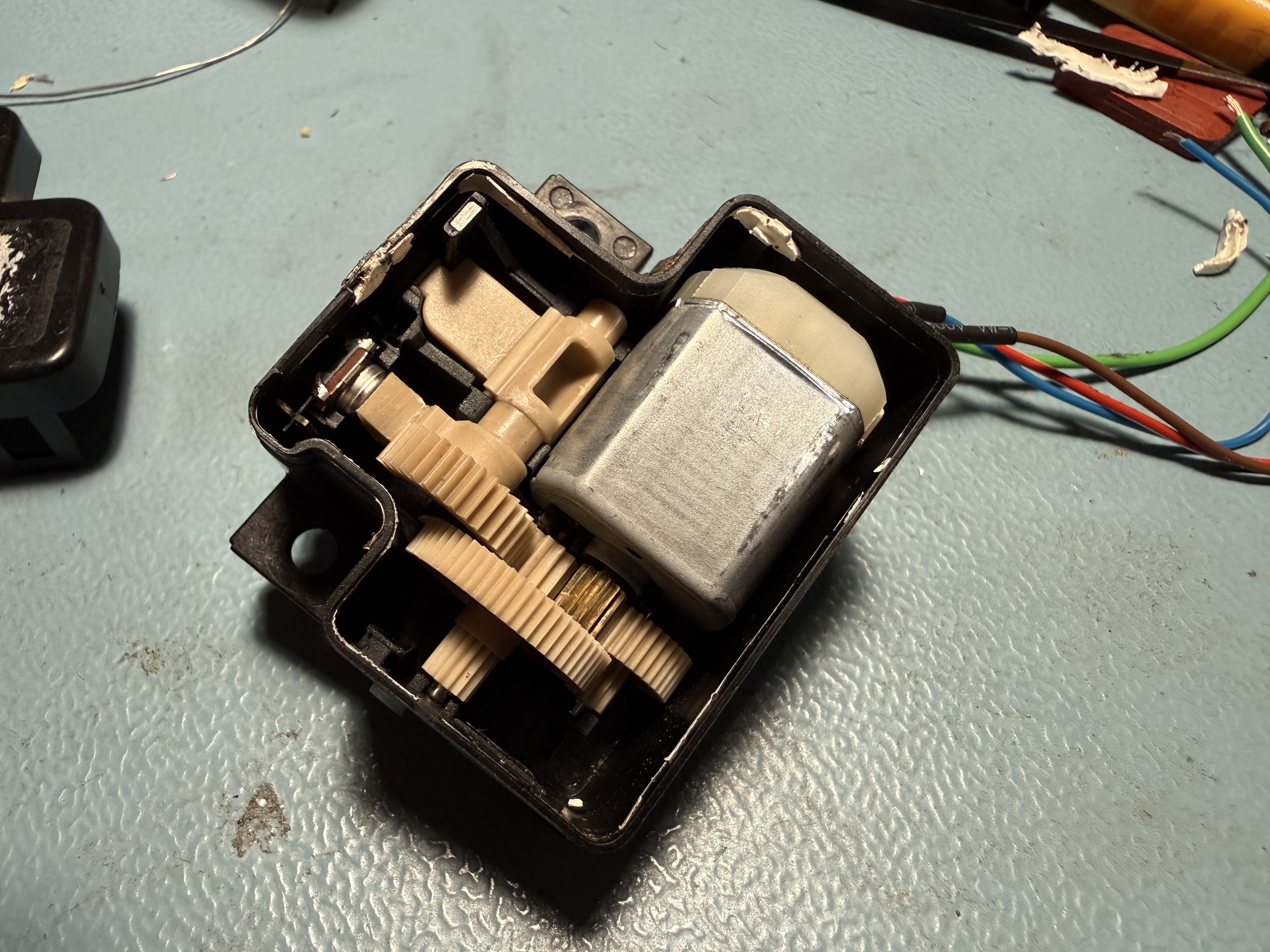

When I picked up the car, I asked if they still had the broken part. For such a price, I want to know the failure mode. Opening it up was easy, and it operates very simple: two wires are for power, and two wires are for signaling. A small cam is turned by the motor, which presses a microswitch on the start and end position. I believe that the controller will measure this, and expects a change of signal when the motor is powered.

Before opening it up, I already noticed that the motor would not spin. But after opening it up and applying some grease, it started to work again. At least it was not dirty on the inside, so it was not due to water ingress. The gears were in good condition too, so I presume that something internally bound, causing the motor to stall and the locking pin to not move. So even though I have it fixed right now, next time it would fail, I would defintely replace the motor with a new one, but then I would do it myself.