A short to ground

Whenever I modify the car, I am always concerned about making things worse. This was one such situation, but it turned out I was not at fault.

Last week, I upgraded the camera from a KA1 to a KA2 model. I needed to add several CAN bus and supply wires from the front of the car to the trunk lid, which required removing a few panels and taping the new wires to the existing loom. Everything worked perfectly for a week with no faults. However, today the head unit displayed a fault with the left-hand side back-up light bulb.

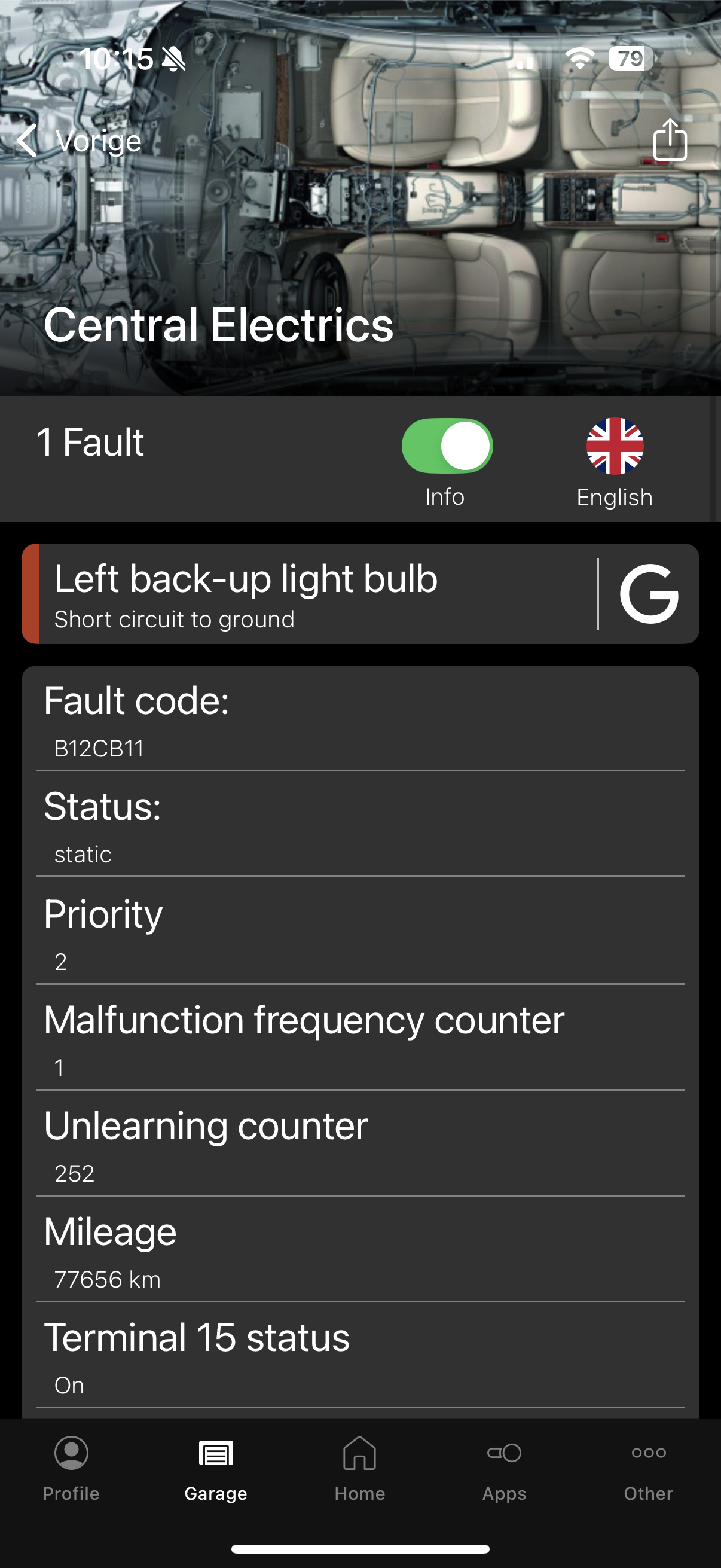

I knew something was wrong: this e-Golf uses only LEDs, and the likelihood of an LED failure is very low. I connected OBDEleven, which revealed the following fault.

A short to ground — never a good sign. The first step I took was to unplug the connector from the inner tail light to see if the error would change. Although this resulted in two additional errors (open circuit and short circuit to B+), the short to ground persisted. This ruled out any issues with the tail light itself.

Next, I used a multimeter to measure between the back-up light bulb pin and ground. This showed a dead short. During last week’s camera installation, I had modified some wiring connected to the back-up light bulb. However, after measuring between these pins and the pin of the light bulb at fault, I found they were not connected. This indicated that the reverse light signal originates from the other back-up light bulb on the right-hand side.

To rule out a wiring issue, I disconnected the two connectors at the trunk lid coupling point (THK). The short measured at the tail light connector disappeared, indicating that the loom in the trunk lid was not damaged. However, there remained a large loom running from the back to the front that could potentially be the source of the problem.

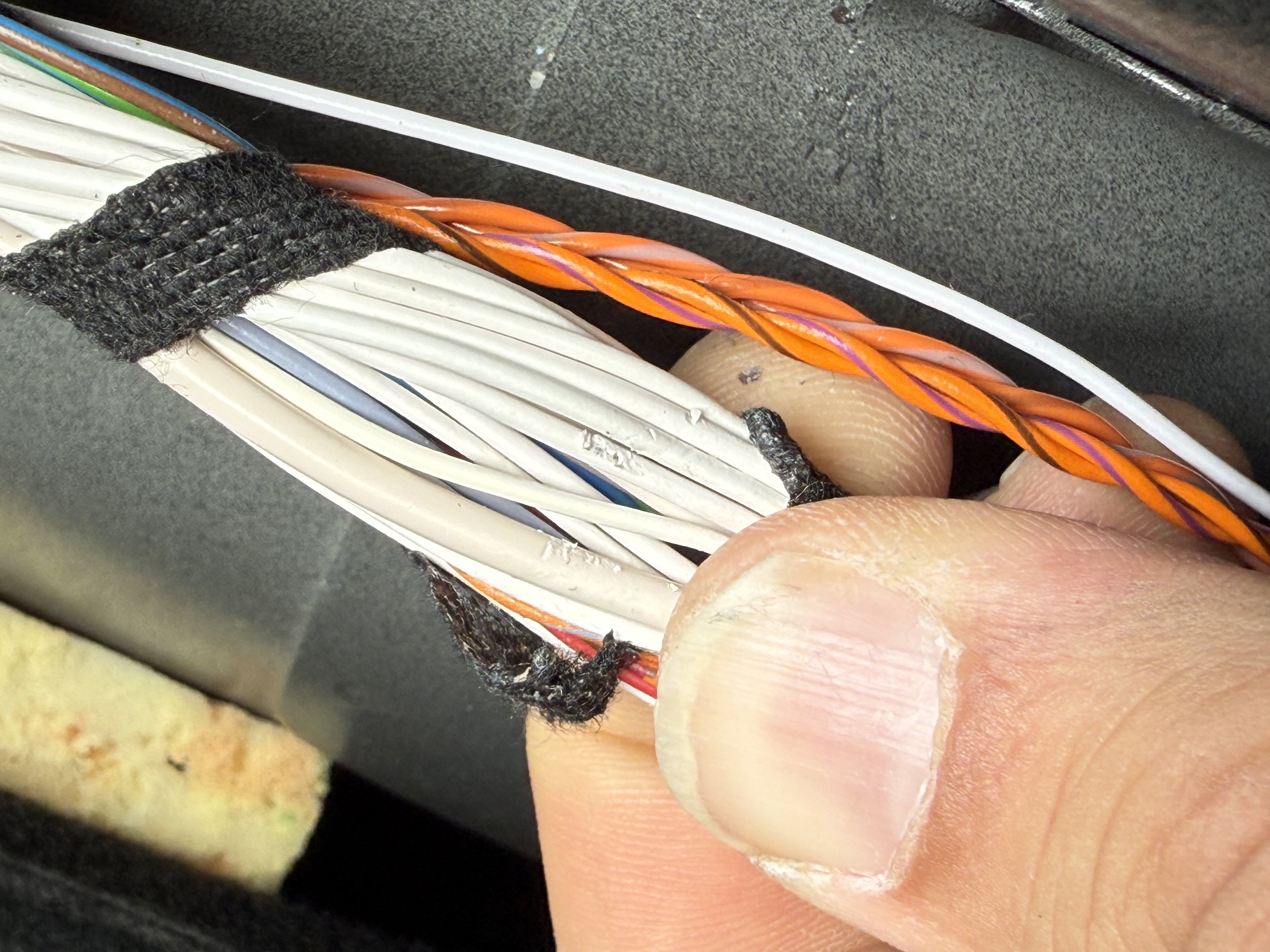

Since all the wires in the loom were properly taped, I did not initially suspect a short to ground via the ground wire. Most of the ground wiring runs through the chassis, so a cut wire seemed more plausible. I began by removing some easily accessible trim pieces: the door sill trim and the side trim next to the back seats. With the multimeter still connected, I wiggled the wire loom and was able to roughly identify where the wire was damaged.

My suspicion was correct — it was a short to the chassis. After some inspection, I discovered the following:

Can you spot it? Let’s move the wire loom aside by removing the plastic clip that secures it to the chassis.

A splinter of metal had cut into the wire loom. It was likely a remnant of the chassis welding process, resembling a small blowout. Two wires had minor damage to their protective insulation, but I did not see any exposed or damaged wire strands, so I was fortunate. I removed the splinter, covered the spot with tape, and wrapped the damaged wires with PVC tape.

I tested the lights before reinstalling all the trim pieces, and the problem was resolved. It still puzzles me why this was not an issue for the previous owner, especially since the car is already seven years old.